All published articles of this journal are available on ScienceDirect.

Evaluation of Occupational Exposure to Silica Dust in Mining Workers in Eastern Iran

Abstract

Background and Objective:

Silica dust is present in almost all mining operations and can cause various health problems such as silicosis in workers. The present study aimed to determine the total and respirable dust levels and the crystalline silica content of the soil in the breathing zone of workers in Iranian mines.

Methods:

This cross-sectional study was carried out in 2016-2017 on six Iranian silica mines. Dust sampling was performed according to the National Institute of Occupational Safety and Health (NIOSH) method No. 0600. The samples were collected from the respiratory zone of workers at 114 stations in different units of the mines. The silica content was measured using the standard NIOSH method No. 7601. The crystalline silica content in bulk samples collected from the soil was determined by using the X-Ray Diffraction (XRD) spectroscopy method.

Results:

The highest concentration of crystalline silica dust was 2.81±0.49 mg/m3 and was observed in the air of crushing unit of mine no. 6, and the lowest was 0.08±0.208 mg/m3 and was measured in the management/administration unit of mine no.1. The mean silica content in the solid surface of the mines was 91%. The total and respirable dust levels in all units of the mines except management/administration were higher than the permissible limit. The free silica content of all collected samples was substantially higher than the permissible limits, and in some cases, it was as much as 100 times above the standard level, which reflects the extremely high risk of working in these mines.

Conclusion:

Exposure of workers with crystalline silica dust in all units was higher than the standard recommended limits. It is imperative to adopt immediate measures based on technical, managerial, and personal protection solutions to reduce the exposure of workers to silica.

1. INTRODUCTION

Tens of thousands of Iranians work in the mining sector and this number is growing every day. According to the 2011 report of the Statistics Center of Iran, there are 5246 operating mines in Iran, which employ 84528 people. A significant portion of these individuals work in silica mines, and specifically in extraction, crushing, processing, and loading units of mines (Dehghan et al., 2009).

Silica or Silicon dioxide (SiO2) is an inorganic compound composed of an atom of silicon and two atoms of oxygen. It is colorless, odorless, and non-combustible and constitutes about 25% of the Earth’s crust. Silica can be found in two general forms: crystalline and non-crystalline. There are several forms of crystalline silica, which include α-quartz, quartz, tridymite, cristobalite, keatite, coesite, stishovite and moganite (Nguyen et al., 1992). Due to the abundance of α-quartz in nature, the term “quartz” is often used in place of crystalline silica. Overexposure to crystalline silica is known to have adverse effects on human health. The factors affecting occupational exposure to respiratory diseases, especially silicosis, in the mining sector are the concentration of silica dust in the place of work, the free silica content of this dust, and the duration of exposure (Aliabadi et al., 2007, Gholami et al., 2018).

Most of the people working in open-pit and underground mines are more or less exposed to silica dust, as it is likely to be present in the site soil and to be released in the course of mining operations. However, this issue is of greater importance to silica mines, where workers could be exposed to extremely high levels of silica dust. Exposure to silica dust is known to cause silicosis, bronchitis, kidney problems, respiratory problems, oxidative effects, and genetic effect (DNA damage), and more so in silica miners than in other miners exposed to silica dust (Kakooei et al., 2012, Gholami et al., 2012a, Başaran et al., 2003, Nguyen et al., 1992). The fact that the International Agency for Research on Cancer (IARC) has classified silica as a group 1 carcinogen (Cancer, 1987) further underscores the necessity of monitoring silica dust level in working environments. According to the American Conference of Governmental Industrial Hygienists (ACGIH), the 8-hour working exposure limit for silica is 0.025 mg/m3 (ACGIH, 2015). In Iran, the Ministry of Health has also set this limit to 0.025 mg/m3 (Iran, 2016).

The presence and quantity of free silica in mines and the occupational exposure of miners to silica dust have been the subject of many studies. Many of these studies have reported that, in most mines, the total and respirable dust levels are higher than the standard exposure limit (Golbabaei et al., 2004, Scarselli et al., 2014, Hayumbu et al., 2008, Azari et al., 2009). A study by Koo et al. (2000) on the exposure to crystalline silica dust showed that the concentration of crystalline silica in the core-making unit was 0.023 mg/m3, which is lower than the limit, but in other units (molding, cleaning, melting) it was higher than the standard limits specified by the National Institute for Occupational Safety and Health (NIOSH) and ACGIH (Koo et al., 2000). In a risk assessment of exposure to silica in six occupational groups, Mannetje et al. (2002) reported that the risk of death from silicosis monotonically increases with cumulative exposure. The estimated risk of silicosis mortality before age 65 after 45 years of exposure to 0.1 mg/m3 of silica (a common standard in many countries) was 13/1000, but for 45 years of exposure to 0.05 mg/m3 of silica, this value was 6/1000 (Mannetje et al., 2002). In a cohort study conducted by Rice et al. on 2342 diatomaceous earth mining and processing workers with exposure to crystalline silica dust, it was reported that the estimated risk of mortality from lung cancer after 45 years of silica exposure at the Occupational Safety and Health Administration (OSHA) standard level (0.05 mg/m3) was 19/1000 (Calvert et al., 2003). Although silica dust-induced respiratory diseases are preventable, they continue to cause disability and mortality among the workers of the mining industry. The best way to preventthesediseases is to assess the risk of exposure to silica dust in different work environments and plan appropriate counter measures depending on the observed dust levels. In the presentstudy, the aim was to assessthe occupationalexposure of Iranian silica miners to silica dust, in the hope that the collected information would provide better insight into the risks of working in the Iranian silica mining industry.

2. METHODS

2.1. Study Setting and Sampling

This cross-sectional study was carried out from 2016 to 2017 on six silica mines in eastern Iran. Sampling was carried out to determine the weighted average of exposure of people working in different units of the mine, including extraction, crushing, processing and loading, and management/ administration to total and respirable dust as measured by the NIOSH method No. 0600. Total dust sampling was performed using a sampling pump, SKC, Inc. equipped with a plastic holder and Mixed Cellulose Ester (MCE) membrane filter (25 mm diameter, 0.8 mm pore size) at a flow rate of 2.8 L/min. Respir able dust sampling was carried out with a plastic cyclone at a flow rate of 1.7 L/min. To minimize the confounding effect of moisture, filters were placed in the desiccator 24 h before and after sampling. The filters were weighted with the DENVER digital scale with a precision of 0.00001 mg. Sample analysis to determine the quantity of crystalline silica was performed according to the NIOSH method No. 7601 (Eller, 1994).

To determine the quantity of silica by UV-Visible spectrophotometry, silica-containing filters were transferred to a beaker, were mixed with 4 mL of nitric acid, and were heated until drying. The same process was repeated two times with the same amount of pure nitric acid until the fume color of filters turned milky white. Next, 25 mL of phosphoric acid was added to the beaker, it was heated to 240°C, and then 125 mL of deionized water was added. The resulting solution was filtered with a Whatman filter paper 45 and the filter was transferred to a polyethylene container holding fluoric acid. After adding water and boric acid to the container, it was heated in a warm water bath, and then molybdate reagent solution was added. Lastly, 10 N sulfuric acid (mL) was added to the solution and the specimens were read after about 10 minutes using the unique 2150D spectrophotometer at 420 nm. The silica content of the bulk samples of the mine soil was measured by the X-Ray Diffraction (XRD) spectroscopy method (Philips, Com.).

2.2. Statistical Analysis

The data were analyzed in SPSS version 21 for quantitative variables, means and standard deviations were computed. The mean total and respirable dust levels and free silica content in different units of the mines were compared with the permiss ible limits using one sample t-test.

3. RESULTS

The measured total and respirable silica dust levels and the silica content of bulk samples varied with the position of measurement. The highest mean total dust level in the studied mines, 17.1 ± 3.9 mg/m3, was observed in crushing units, and the lowest, 3.1 ± 0.9 mg/m3, belonged to management/ admin istration units. Table 1 shows the total dust levels in different units of the mines and their silica contents. The highest silica content in the total dust samples was also observed in the samples of crushing units.

| Unit | Dust | Mine 1 | Mine 2 | Mine 3 | Mine 4 | Mine 5 | Mine 6 |

|---|---|---|---|---|---|---|---|

| Extraction | Total | 15.3±2.8 | 16.2±3.9 | 16.2±2.7 | 16.2±2.1 | 12.9±3.2 | 18.2±3.8 |

| Silica content | 1.83±0.67 | 1.78±0.72 | 1.64±0.81 | 2.09±0.71 | 2.23±0.62 | 2.03±0.58 | |

| Crushing | Total | 18.2±3.8 | 18.7±3.9 | 19.2±4.1 | 17.2±3.2 | 20.2±4.2 | 19.7±3.2 |

| Silica content | 2.18±0.54 | 2.57±0.45 | 2.49±0.67 | 1.93±1.83 | 2.62±0.72 | 2.89±0.49 | |

| Wet processing | Total | 5.7±1.3 | 6.1±1.7 | 4.8±0.98 | -* | - | - |

| Silica content | 0.79±0.48 | 0.854±0.39 | 0.816±0.54 | - | - | - | |

| Dry processing | Total | 12.7±3.4 | 13.3±2.9 | 12.9±1.8 | 14.2±2.7 | 12.7±2.1 | 15.7±1.9 |

| Silica content | 1.89±0.78 | 1.98±0.68 | 2.19±0.42 | 2.14±0.54 | 2.03±0.62 | 2.13±0.58 | |

| Loading | Total | 11.3±2.9 | 10.9±2.1 | 11.8±3.1 | 12.2±2.2 | 11.5±1.9 | 9.8±2.1 |

| Silica content | 2.19±0.78 | 2.071±0.62 | 36.2±0.52 | 2.56±0.49 | 2.37±0.63 | 2.5±0.54 | |

| Management/ administration | Total | 3.1±0.9 | 4.1±1.3 | 2.8±0.9 | 3.2±0.98 | 3.8±0.78 | 2.9±0.74 |

| Silica content | 0.588±0.08 | 0.451±0.091 | 0.336±0.07 | 0.512±0.12 | 0.494±0.16 | 0.522±0.18 |

| Unit | Dust | Mine 1 | Mine 2 | Mine 3 | Mine 4 | Mine 5 | Mine 6 |

|---|---|---|---|---|---|---|---|

| Extraction | respirable | 7.2±2.1 | 6.9±2.3 | 7.2±1.9 | 6.5±1.9 | 8.7±1.8 | 7.5±1.7 |

| Silica content | 1.08±0.11 | 1.104±0.13 | 0.98±0.08 | 1.18±0.14 | 0.957±0.21 | 1.12±0.19 | |

| Crushing | respirable | 10.4±2.1 | 11.3±2.7 | 10.9±1.8 | 12.3±2.1 | 10.8±1.8 | 11.7±1.9 |

| Silica content | 1.45±0.17 | 1.808±0.33 | 1.85±0.23 | 2.09±0.41 | 1.404±0.18 | 1.87±0.32 | |

| Wet processing | respirable | 3.2±0.98 | 2.9±0.87 | 4.2±1.3 | -* | - | - |

| Silica content | 0.544±0.08 | 0.561±0.09 | 0.756±0.12 | - | - | - | |

| Dry processing | respirable | 7.3±2.1 | 6.9±1.8 | 7.2±1.9 | 6.5±1.8 | 7.4±1.9 | 8.3±2.9 |

| Silica content | 1.38±0.41 | 1.24±0.39 | 1.51±0.24 | 1.105±0.29 | 1.702±0.31 | 1.99±0.42 | |

| Loading | respirable | 7.1±2.1 | 6.9±1.9 | 7.2±2.1 | 8.6±1.8 | 8.8±1.9 | 8.9±2.3 |

| Silica content | 1.49±0.19 | 1.58±0.31 | 1.36±0.29 | 1.23±0.41 | 1.71±0.27 | 2.044±0.41 | |

| Management/ administration |

respirable | 1.7±0.7 | 1.9±0.07 | 2.1±0.26 | 1.8±0.15 | 1.4±0.18 | 2.1±0.17 |

| Silica content | 0.205±0.08 | 0.323±0.09 | 0.378±0.08 | 0.28±0.13 | 0.261±0.09 | 0.215±0.11 |

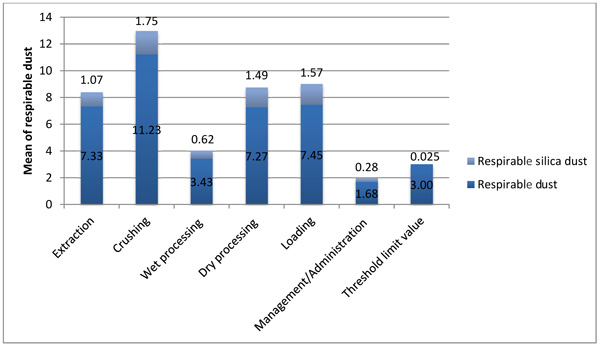

The highest mean respirable dust level in the mines was 10.4 ± 3.2 mg/m3, which belonged to crushing units, and the lowest was 1.3 ± 0.08 mg/m3 and belonged to management/ administration units. The respirable dust levels in different units of the mines and their silica contents are presented in Table 2.

Table 3 shows the mean and standard deviation of the silica content of the bulk samples obtained from different units of the mines. The highest mean silica contents in these samples were 98%, which belonged to the samples obtained from processing and loading units, respectively.

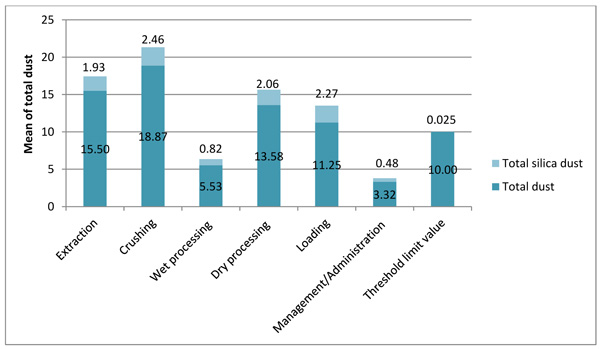

In Figs. (1 and 2), the mean total and respirable silica dust levels in different units of the mines are compared with standard recommended limits. The mean total and respirable silica dust levels in all units of the mines are significantly higher than the standard exposure limit (P < 0.05).

4. DISCUSSION

The measurements made in six Iranian silica mines showed that the highest total and respirable dust levels belonged to crushing units and the lowest levels were related to management/administration units. At all measurement stations except wet processing and management/administration, the total and respirable dust levels were higher than the ACGIH exposure limits. The current ACGIH recommendations as well as the exposure limits recommended by The Technical Safety and Occupational Health Committee of Iran for inhalable and respirable dusts are 10 and 3 mg/m3, respectively (ACGIH, 2015, Iran, 2016). The level of silica dust in all units, even in management/ administration units, was higher than the occupational exposure limit. Several studies on the occupational exposure of different workers to silica dust have shown that, in most workplaces that have a potential for silica dust exposure, the concentration of silica dust exceeds the allowed occupational limits (Aliabadi et al., 2007, Gholami et al., 2012b, Golbabaei et al., 2004)

| Sampling Unit | Silica (%) |

|---|---|

| Extraction | 82±4.2 |

| Crushing | 86±2.1 |

| Dry processing | 98±1.2 |

| Loading | 98±1.1 |

In a study conducted by Hayumbu et al. (2008) on two mines in Zambia, the silica levels in these mines were 59% and 26%, and the quantity of free silica dust was 0.992 and 0.888 mg/m3, which are all higher than the permissible exposure limit, but are still significantly lower than the silica dust levels observed in the present study. The silica contents measured in the present study are also higher than those reported in that study (Hayumbu et al., 2008). In a study performed by Golbabaei et al. on the Senjedak building stone mine, the silica dust level was 0.67 mg/m3, which was higher than the exposure limit to silica dust in this study (Golbabaei et al., 2004). The study carried out by Aliabadi et al. (2007) on Azandarian stamping workshops in Hamedan, the silica content of the samples ranged between 85 and 97%, and dust concentration in the first-grade and second-grade workshops was 0.2 and 0.45 mg/m3, respectively. In that study, dust concentration in the air of the examined workshops was higher than the occupational exposure limit, but the reported values are still significantly lower than the corresponding values for the mines investigated in the present study (Aliabadi et al., 2007). In research on the exposure of Italian workers to silica, miner has the second highestexposure to silica (after construction workers), and the average level of silica dust in mines was reported to be 0.048 mg/m3, which is several times lower than the dust levels measured in the silica mines of the present study (Scarselli et al., 2014). In a study conducted in India, the silica content measured in mines was less than 5%, and the dust level in the air varied from 0.05 to 9.48 mg/m3. These values are somewhat closer to the measurements made in some units in the present study (Mukherjee et al., 2005). Azeri et al., which studied 10 groups of people with exposure to silica, also reported that silica dust concentrations in all groups were higher than the permissible occupational exposure limit (Azari et al., 2009).

By comparing the results of this study with the reports of other studies, it can be concluded that although many occupations are exposed to silica dust at levels higher than the exposure limit, the total and respirable silica dust levels in Iranian silica mines are extremely higher than in other work environments. In some units of the investigated mines, the silica dust level was 450 times higher than the allowed limit, which reflects an extremely high risk for people working in these areas. The comparison of dust concentrations in different units of silica mines showed that crushing units had higher dust levels than the rest of the mine. After comparing the dust levels in the wet and dry treatment units, it was found that although the silica dust concentrations in the wet treatment units were higher than the allowed exposure limit, they were significantly lower than the concentrations in the dry units. The reasons behind the high levels of dust and their high silica contents in the investigated mines could be the use of worn-out mining equipment, exposure to seasonal winds, the use of unroofed and uncontrolled depots within the perimeter.

Enforcing preventive standards for the health and safety of workers, creating personal health records for miners, and raising workers’ awareness about the health hazards of exposure could prove effective in dealing with the observed problem. Employers should also be required to use advanced mechanized systems to minimize the direct exposure of workers to silica-containing dust.

CONCLUSION

Given the amount of silica contained in the samples of the investigated mines and the amount of dust in their air work environments, the total and respirable dust levels and silica concentrations in these mines are extremely higher than the occupational exposure limit. Considering the high level of silica dust exposure in these mines, which in some area is 100 times higher than the exposure limit, the immediate adoption of proper countermeasures to prevent dust-induced diseases is imperative. The results suggest that the use of wet treatment systems and simultaneous control of ventilation water may be able to reduce the risk of exposure to silica dust. Given that the investigated silica mines are open pits and exposed to seasonal winds, which makes it difficult to control the work environment, it is recommended to enforce the use of respiratory protective equipment in all units of the mines.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

No animals/ humans were used for the studies that are the basis of this research.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

Not applicable.

FUNDING

None declared.

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.

REFERENCES

[CrossRef Link] [PubMed Link]

[CrossRef Link] [PubMed Link]

[CrossRef Link] [PubMed Link]

[CrossRef Link] [PubMed Link]

[PubMed Link]

[CrossRef Link]

[CrossRef Link] [PubMed Link]

[CrossRef Link] [PubMed Link]

[CrossRef Link] [PubMed Link]

[CrossRef Link] [PubMed Link]

[CrossRef Link]